OEM Coin Technology – Cost effective technology for bulk coin applications

World Class Coin Counting and Sorting Technology

In order for our OEM customers to experience the implementation of the CTcoin coin technology as smoothly and easily as possible into specified applications, CTcoin has developed an “OEM procedure”. This procedure takes you step-by-step through the process. Please don’t hesitate to contact us for a copy of our OEM procedure!

OEM Brochure

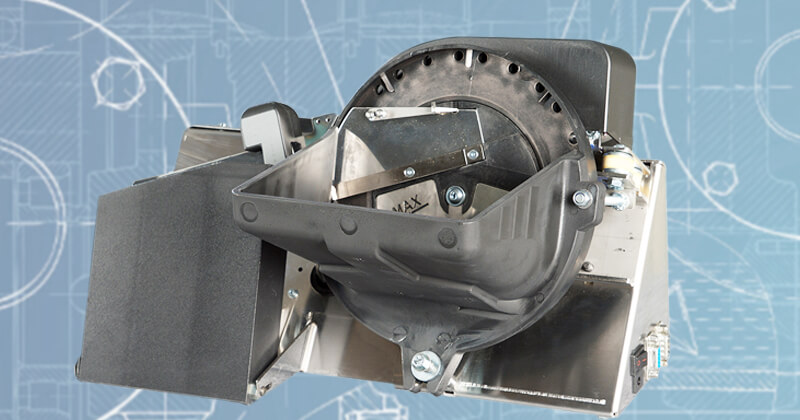

Delta/Basic coin counter/sorter technology

The Delta/Basic coin counter and sorter with coin bowl, pickup wheel, counting sensor and reject solenoid function. Fully electronic with embedded real time software for coin recognition and handling up to 20 different denominations

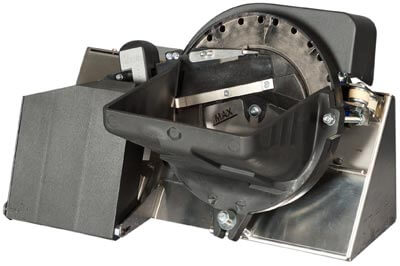

Compac coin counter/sorter technology

The Compac is a brand new patented and compact coin module with outstanding accuracy, durability and reliability counting up to 300 cpm.

CTcoin V5 – The 5th generation of coin counting and sorting technology

All CTcoin units have the new 5th generation of electronics called V5 (version 5) introduced in 2014, using the most modern technology of electronics available in the world market.

The CTcoin patented coin sensor technology is incorporated into a free flowing coin pickup and coin rail sorting mechanism. The sensor identifies each coin by size and metal content using 16 parameters for a precise and sophisticated detection of each coin.

The coin pickup has a finger deflector to prevent coin pyramids and to ensure a clean and steady coin flow through the sensor. The reject function is performed by a solenoid controlled timed kick-out valve by way of a coin validation algorithm with a speed of up to 1,100 coins per minute.

The concept description is valid for the technology as of January 2015. CTcoin reserves the right to enhance, simplify, change or update any part of the concept at any time without notice.

V5 technology advantages

- No wearing parts

- High reliability

- Ease of service

- Low cost unit

- Relatively silent unit

V5 technology limitations

- Relative speed (from 230-1100 cpm)

- Not all currencies/coin sets can be handled or processed

- Free flow – small but present likelihood of “jumping” coins

| Unit type | Outlets | Sorting | Cleaning System | Coin bowl sensor | Coins per minute |

|---|---|---|---|---|---|

| Delta/Basic 01 | 1 | No | Optional | Optional | 1,100 |

| Delta/Basic 05 | 5 | Yes | Optional | Optional | 1,100 |

| Delta/Basic 09 | 9 | Yes | Optional | Optional | 1,100 |

| Delta/Basic 22 | 2 | No | Optional | Optional | 1,100 |

| OEM CDS 01 | 1 | No | Yes | Yes | 1,100 |

| OEM CDS 06 | 6 | Yes | Yes | Yes | 1,100 |

| OEM CDS 09 | 9 | Yes | Yes | Yes | 1,100 |

| OEM CDS 26 | 6 mixed | No | Yes | Yes | 1,100 |

| COMPAC 01 | 1 | No | Optional | Optional | 300 |

| COMPAC 05 | 5+1 | Yes | Optional | Optional | 300 |

| COMPAC 08 | 8+1 | Yes | Optional | Optional | 300 |

Get in direct contact with the world’s no 1 coin counting and sorting machine manufacturer

Contact me if you want to know more about our cost effective technology for bulk coin applications. We would be delighted to assist you in pursuing the ideal solution for your business.

Søren Krog | Managing Director and Partner

Tel: +45 6312 7556 | E-mail: sk@ctcoin.com